2023/3/6

Invisible Innovation | XLANCE®

XLANCE®, the original EOL yarn

It was 2003 when the DOW Chemical Company invented a new polyolefin yarn and launched it on the market, calling it XLA. The new-born elastomeric fibre, called elastolefin, specifically designed to possess high elasticity performance, immediately emerged as a better and more sustainable alternative to spandex. Thanks to its unique thermal and chemical resistance, it guarantees long-lasting elasticity and gives long-lasting stretch comfort to the fabrics in which it is used.

In order to be classified and recognised as an elastolefin, the product must possess a durable elasticity and unique chemical and heat resistance characteristics that require special processing and processes that only XLANCE® can undergo.

To date, XLANCE® is the only product on the market that can be classified in this way, making it the unique and original EOL yarn.

Boost, XLANCE® makes anything elastic

from Polypropylene to extra white and non-iron clothing

Easy set

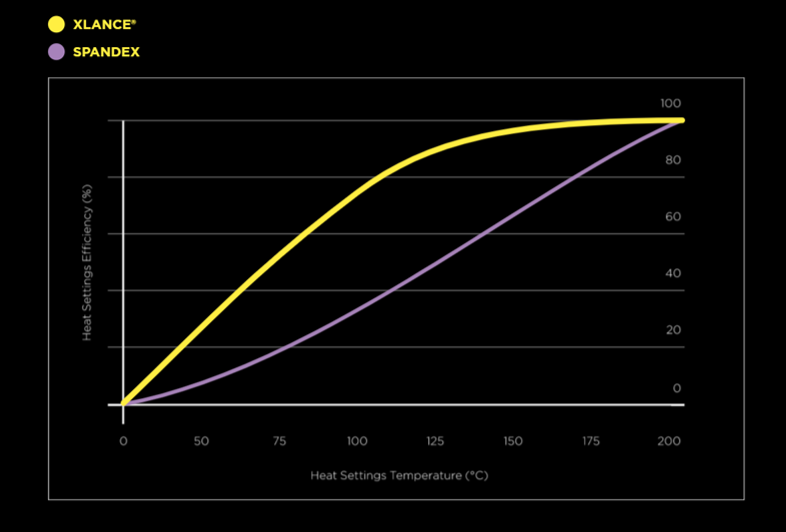

XLANCE® is heat set at 120°C, just above the crystal melting-temperature (against 185-190°C required for spandex). This is due to its molecular architecture and enables the combination with thermosensitive fibers, as well as guaranteeing significant energy and pollution savings.

Power, XLANCE® makes elasticity durable

thanks to its unique chemical and thermal resistance

Acid test

XLANCE® is characterized by the absence of any easily-attackable group in his polyolefin backbone and by the presence of the covalent crosslinks. This gives XLANCE® an excellent resistance to any aggressive chemical agents, such as strong acids, alkalis, oxidizing agents, enzyme wash conditions.

Figure 1_1 ml of concentrated (98%) sulphuric acid was applied to the center of a denim fabric containing XLANCE® for 4 hours, before rinsing with water: XLANCE® yarn remains fully intact.

Heat test

XLANCE® can withstand temperatures up to 220°C without compromising its integrity and stretch performance thanks to the covalent crosslinks. This makes it suitable for high-temperature textile processes.

Figure 2_ Micrographs comparing XLANCE® and spandex fibers before and after 3 minutes treatment at 220 ± 3 °C. Fibers were placed on a slide side by side, covered with slipcover and placed on a hot stage. After cooling, the slipcover was gently removed, leading to the disintegration of spandex but not of XLANCE®.

UV test

XLANCE® yarn is inherently resistant to UVA and UVB radiations.

Stretch test

XLANCE® features an innovative gentle stretch power, completely different from the typical high stretch power of spandex. The force required to stretch XLANCE® is much lower than the one to be applied to spandex. This accounts for the unique comfort stretch feeling of XLANCE® shaping fabrics.

ECO, XLANCE® makes elasticity sustainable

Clean process, durable and recyclable fabric

Solvent free

XLANCE® is produced through a clean melt spinning process, different from the dry-spinning (chemical) one of spandex that involves the use of dangerous solvents like DMAC or DMF.

Renewable energy

XLANCE® is sourcing 100% of its electric power needs from renewable energy.

Low CO2 emissions

XLANCE® can be heat set at just 120°C ensuring the manufacturers substantial energy and costs savings and a relevant reduction in CO2 emissions.

Extended life cycle

The test was performed on rameause with 10 vertical chain fields fed with natural gas indirect (CH4).The reduction in temperature to carry out the fabric thermofixing operation allows to reduce the consumption of natural gas (CH4) by 32 mc/h and consequently to reduce CO2 emissions by 44% (reduction of CO2 emissions by 63.1 Kg/h of CO2).

XLANCE® features a long-lasting stretch which guarantees an extended life cycle to all garments made of it. This entails a lower resource consumption and waste production, for a lower environmental footprint.

Low microplastic release

Thanks to its extreme chemical/ physical resistance, XLANCE® has no tendency to fragmentation and microfiber shedding, not even after exposure to harsh agents, weathering or ageing.

Make it circular

XLANCE® is always looking for new solutions that make sustainable not only the product, but also the entire production process, having a more systemic and holistic vision of the entire textile chain. The chemical component separation and material regeneration is one of the solutions that XLANCE® is trying to put in place, in the perspective of a sustainable development.

Collaborator:XLANCE srl

If need to get more informaiton please refer to www.xlancefibre.com and the wechat account: 意大利XLANCE 弹力纤维

Authority in Charge: China National Textile and Apparel Council (CNTAC)

Sponsor: China Textile Information Center (CTIC)

ISSN 1003-3025 CN11-1714/TS

© 2026 China Textile Leader, all rights reserved.

Powered by SeekRay